The Cessna 150M Parts Manual is an essential resource for maintaining and repairing the 1975 Cessna 150M aircraft. It provides detailed part numbers, diagrams, and specifications to ensure compliance with FAA standards and proper aircraft functionality. This manual is designed to guide owners and technicians through routine maintenance, repairs, and upgrades, ensuring safety and efficiency in all operations.

1.1 Overview of the Cessna 150M Aircraft

The Cessna 150M is a lightweight, all-metal, tricycle-gear aircraft introduced in 1959. Known for its affordability and ease of handling, it is widely used for flight training and personal aviation. The 150M model, produced in 1975, features a 100-hp Continental O-200-A engine, a maximum gross weight of 1,600 lbs, and a top speed of 125 mph. Its simple design and forgiving nature make it an ideal choice for pilots seeking reliability and efficiency.

1.2 Purpose of the Parts Manual

The Cessna 150M Parts Manual serves as a comprehensive guide for identifying, sourcing, and installing genuine aircraft components. It ensures compliance with FAA regulations by detailing specifications, part numbers, and diagrams. This manual is essential for maintenance technicians and owners, enabling them to perform repairs efficiently and maintain the aircraft’s airworthiness. Its detailed information supports routine maintenance and troubleshooting, ensuring operational safety and longevity of the aircraft.

Historical Background and Development

The Cessna 150M evolved from the 150 series, introduced in 1959, featuring improvements like a tricycle landing gear and enhanced performance, making it a popular training aircraft.

2.1 Evolution of the Cessna 150 Series

The Cessna 150 series debuted in 1959, revolutionizing general aviation with its tricycle landing gear and forgiving flight characteristics. Over the years, improvements like increased gross weight, better engines, and aerodynamic tweaks enhanced performance. The 150M, introduced in 1975, became a favorite for flight training and personal use, with its robust design and reliability. Its enduring popularity stems from continuous refinements and a focus on pilot accessibility.

2.2 Key Features of the Cessna 150M Model

The Cessna 150M features a Continental O-200-A engine, producing 100 horsepower, with a maximum gross weight of 1600 lbs. It boasts a top speed of 125 mph and a cruise speed of 122 mph. Known for its simplicity and affordability, the 150M is equipped with a tricycle landing gear, making it stable and easy to handle. Its durable design and low operating costs make it ideal for flight training and personal use.

Key Components and Systems

The Cessna 150M features a durable airframe, a Continental O-200-A engine, and essential avionics. Its systems include electrical, fuel, and hydraulic components, ensuring reliable performance and safety.

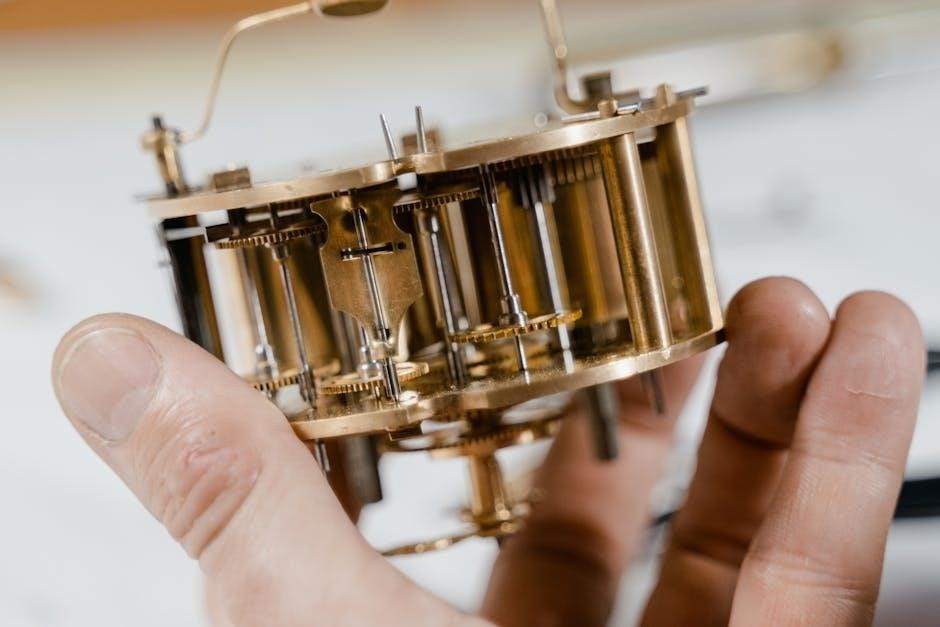

3.1 Airframe and Structural Components

The Cessna 150M’s airframe is constructed from durable aluminum alloys, ensuring strength and lightweight performance. The tricycle landing gear provides stability, while the wings and control surfaces are designed for optimal aerodynamics. The fuselage is reinforced for safety, and all structural components are detailed in the parts manual with specific part numbers for easy identification and replacement.

3.2 Engine and Propeller Specifications

The Cessna 150M is powered by a Continental O-200-A engine, producing 100 horsepower at 2,750 RPM. The engine features a direct-drive system and air-cooled design for reliability. The propeller is a fixed-pitch Sensenich 72CK56-0-54, optimized for both takeoff and cruise performance. The parts manual provides detailed specifications, torque values, and inspection intervals for engine and propeller maintenance, ensuring optimal functionality and compliance with FAA standards;

3.3 Avionics and Electrical Systems

The Cessna 150M features a basic yet reliable avionics system, including a communication radio, navigation instruments, and essential electrical components. The aircraft’s electrical system operates on a 12-volt battery and alternator setup, powering critical systems like lights, avionics, and engine starters. The parts manual provides detailed schematics, wiring diagrams, and part numbers for components such as circuit breakers, relays, and antennas, ensuring efficient troubleshooting and maintenance of the electrical and avionics systems.

Maintenance and Repair Procedures

The Cessna 150M Parts Manual outlines essential maintenance and repair procedures, including routine inspections, component replacements, and troubleshooting. It ensures compliance with safety standards and regulations.

4.1 Routine Maintenance Tasks

Routine maintenance tasks for the Cessna 150M include oil changes, tire pressure checks, and air filter inspections. These procedures ensure optimal performance and safety. The parts manual provides detailed schedules and guidelines for these tasks, helping owners and technicians maintain the aircraft’s integrity and extend its service life. Regular inspections of critical systems, such as brakes and electrical components, are also emphasized to prevent unforeseen issues during operation.

4.2 Troubleshooting Common Issues

Troubleshooting common issues in the Cessna 150M involves identifying problems like engine malfunctions or electrical system faults. The parts manual provides diagnostic procedures to trace issues to specific components. For example, addressing spinner assembly discrepancies or resolving electric flap motor failures requires referencing detailed repair guides. Regular inspections and adherence to manual instructions help pinpoint and resolve problems efficiently, ensuring the aircraft remains airworthy and operational.

Parts Identification and Procurement

The Cessna 150M parts manual provides detailed part numbers, diagrams, and descriptions to help identify and procure genuine components. This ensures compliance with safety and performance standards.

5.1 Understanding Part Numbers and Diagrams

The Cessna 150M parts manual includes detailed part numbers and diagrams to help users identify components accurately. Each part number is structured with prefixes and suffixes, indicating its function and compatibility. Diagrams provide visual representations of assemblies, making it easier to locate and verify parts. This system ensures maintenance personnel can quickly reference and order genuine Cessna parts, maintaining compliance with FAA standards and ensuring safety.

5.2 Sourcing Genuine Cessna Parts

Acquiring genuine Cessna parts ensures reliability and compliance with safety standards. The Cessna Dealer Network offers authentic components, supported by service manuals and updates. Additionally, online platforms and authorized distributors provide convenient access to verified parts. Using genuine components guarantees proper fitment and performance, reducing the risk of failures and maintaining the aircraft’s airworthiness. Always cross-reference part numbers with the manual to ensure authenticity and compatibility.

Safety Guidelines and Precautions

Adhering to safety guidelines is crucial when working with the Cessna 150M. Always follow proper tool usage, wear protective gear, and comply with regulations to ensure safe maintenance and operation.

6.1 Handling and Storage of Parts

Proper handling and storage of Cessna 150M parts are critical to maintain their integrity. Clean parts thoroughly before storage, using protective materials to prevent damage. Store in a dry, climate-controlled environment to avoid corrosion. Use original packaging when available to ensure safety and organization. Label parts clearly and keep them in designated areas to prevent loss or misplacement. Always handle fragile components with care to avoid accidental damage.

6.2 Safety Protocols During Maintenance

Adhering to safety protocols during Cessna 150M maintenance is crucial to prevent accidents and ensure compliance with aviation standards. Always wear protective gear, including gloves and safety glasses, when handling tools or components. Ensure proper ventilation when using chemicals, and consult safety data sheets for specific precautions. Secure the aircraft to prevent movement, and follow manufacturer guidelines for tool usage. Maintain a clean workspace and have an emergency plan in place for unexpected situations.

Tools and Equipment Required

Essential tools for maintaining the Cessna 150M include wrenches, screwdrivers, and specialized equipment for repairs. Ensure all tools comply with Cessna’s maintenance guidelines.

7.1 Essential Tools for Maintenance

Essential tools for maintaining the Cessna 150M include combination wrenches, socket sets, screwdrivers, pliers, and torque wrenches. Specialized tools like rivet guns and sheet metal tools are also required. Ensure all tools meet Cessna’s specifications for safety and compatibility. Proper tool organization and condition are critical to efficiently perform routine and complex maintenance tasks outlined in the parts manual.

7.2 Specialized Equipment for Repairs

Specialized equipment for Cessna 150M repairs includes rivet guns, sheet metal tools, and hydraulic presses for forming parts. Diagnostic tools like aviation multimeters and compression testers are essential for evaluating engine and electrical systems. Alignment jigs ensure accurate repairs of structural components. All equipment must meet Cessna’s specifications to guarantee safety, precision, and compliance with FAA standards during maintenance and repair operations.

Compliance and Regulatory Considerations

This section outlines the importance of adhering to FAA regulations, utilizing service letters, and maintaining detailed documentation as per the Cessna 150M parts manual guidelines.

8.1 Adherence to FAA Regulations

Adhering to FAA regulations is critical for the safe operation and maintenance of the Cessna 150M. The parts manual ensures compliance by providing detailed part specifications, service letters, and maintenance protocols. Proper documentation and adherence to these guidelines are essential for maintaining airworthiness and meeting regulatory standards. Cessna Dealers and authorized service centers play a key role in ensuring all repairs and upgrades comply with FAA requirements, guaranteeing safety and reliability.

8.2 Documentation and Record-Keeping

Accurate documentation and record-keeping are vital for maintaining the Cessna 150M’s airworthiness. The parts manual emphasizes the importance of detailed service records, part installation logs, and compliance tracking. Proper documentation ensures traceability of parts and adherence to maintenance protocols. Cessna Dealers and authorized centers provide standardized formats for recording repairs, ensuring transparency and accountability. Maintaining precise records is essential for regulatory audits and long-term aircraft integrity.

Advanced Repair and Modification Techniques

The Cessna 150M parts manual provides detailed guidance for advanced repairs and modifications, including upgrades and customizations. It ensures compliance with FAA standards and enhances aircraft performance.

9.1 Upgrading and Customizing the Aircraft

The Cessna 150M parts manual offers guidance for upgrading and customizing the aircraft, including engine performance enhancements and avionics upgrades. It provides detailed instructions for modifying systems while ensuring compliance with FAA standards. Customizations can improve functionality, aesthetics, or performance, but require careful planning and adherence to safety protocols. The manual emphasizes the importance of using genuine parts and consulting certified professionals for complex modifications to maintain airworthiness and reliability.

9.2 Approving and Certifying Modifications

Approving and certifying modifications for the Cessna 150M requires strict adherence to FAA regulations and guidelines. All modifications must be documented and submitted for review to ensure compliance with airworthiness standards. Certified professionals, such as FAA-licensed mechanics, must approve changes to guarantee safety and performance; The parts manual emphasizes the importance of using genuine Cessna parts and following authorized procedures to maintain certification and operational integrity.

Common Challenges and Solutions

Common challenges include parts availability and maintenance costs. Solutions involve sourcing genuine parts and regular maintenance to ensure optimal performance and safety of the Cessna 150M.

10.1 Overcoming Parts Availability Issues

The Cessna 150M parts manual highlights the importance of sourcing genuine parts to maintain safety and compliance. Challenges arise when specific components are scarce. Solutions include consulting the parts catalog for alternatives, contacting authorized Cessna dealers, or leveraging online forums for community support. Regular maintenance and proactive ordering can mitigate delays, ensuring uninterrupted aircraft operation and adherence to FAA standards.

10.2 Managing Maintenance Costs

Effective cost management for Cessna 150M maintenance involves budgeting for routine tasks, such as inspections and part replacements. Prioritizing preventive maintenance can reduce unexpected repair expenses. Sourcing genuine parts from authorized dealers or online forums ensures quality and compliance. Planning for contingencies and leveraging cost-effective solutions, like refurbished components, helps optimize financial resources while maintaining safety and performance standards.

Resources and Support

The Cessna 150M parts manual is supported by a network of authorized dealers, online forums, and technical documentation. These resources provide access to genuine parts, expert advice, and community-driven solutions, ensuring efficient maintenance and compliance with safety standards.

11.1 Cessna Dealer Network and Support

The Cessna Dealer Network offers comprehensive support for the 150M, providing genuine parts, service manuals, and expert assistance. Dealers maintain up-to-date resources, including parts catalogs and technical documentation, ensuring compliance with FAA standards. Their expertise and access to official Cessna materials make them the primary source for reliable maintenance and repairs, guaranteeing safety and optimal aircraft performance.

11.2 Online Forums and Communities

Online forums and communities provide valuable resources for Cessna 150M owners and technicians. Platforms like Studylib and dedicated aviation forums offer access to manuals, troubleshooting guides, and expert advice. These communities foster collaboration, allowing members to share experiences and solutions for common issues. They are invaluable for sourcing hard-to-find parts and gaining insights from experienced pilots and mechanics, ensuring effective maintenance and repair practices.

The Cessna 150M Parts Manual is a vital tool for ensuring proper maintenance and safety. By following its guidelines, owners can maintain their aircraft’s reliability and longevity, adhering to FAA standards and promoting safe flight operations.

12.1 Importance of Proper Maintenance

Proper maintenance is critical for ensuring the safety, reliability, and longevity of the Cessna 150M. Regular inspections and adherence to the parts manual’s guidelines prevent mechanical failures and ensure compliance with FAA standards. Timely repairs and replacements of worn or damaged components enhance performance and reduce operational risks. By following the manual, owners can maintain their aircraft’s airworthiness and ensure safe, efficient flight operations for years to come.

12.2 Final Thoughts on the Cessna 150M Parts Manual

The Cessna 150M Parts Manual is a comprehensive guide that empowers owners and technicians to maintain and repair their aircraft effectively. Its detailed part numbers, diagrams, and procedures ensure compliance with safety standards and optimal performance. By leveraging this resource, users can extend the lifespan of their aircraft, reduce maintenance costs, and uphold the legacy of this reliable and iconic plane in aviation history.